24 Jan Market Share Expansion Through Product Innovation with AI

Unless your company is certain it has saturated its core market, it’s generally more profitable and less risky to employ value creation capital to expand market share (find new customers in current markets) rather than to expand markets (find new customers in new markets). Customer retention, pricing optimization, product competitiveness, marketing and distribution all factor into organic market share growth. In addition to the role smart tech plays in retention and pricing, discussed earlier, it also plays two new and meaningful roles in market share expansion: defining the ideal customer profile (ICP) to market to, and making a product more competitive. Here we’ll focus on the latter: how smart tech can make a physical product smart and highly competitive.

We all own some type of smart product: a smart watch, a smart thermostat, a smart car or the OG of smart, a smart phone. All share two technical characteristics: they are software-defined and data-driven. But more importantly they’re usually the most valued products in their category because they are the most innovative and differentiated. This leads to, not only market share expansion, but also increased profitability, barriers to entry, bargaining power and brand recognition.

We all own some type of smart product: a smart watch, a smart thermostat, a smart car or the OG of smart, a smart phone. All share two technical characteristics: they are software-defined and data-driven.

To make a product smart we go back to software-defined and data-driven. If the product is already software, it’s already software-defined so the work is in making the code data-driven. If the product is physical, we need to represent it digitally. This step is called virtualization and it’s defined by the smart product’s digital twin. Most twin how a product looks and operates, such as with a CAD model, but for value creation we twin the value it produces or a facsimile of such.

Take for example a medical device I worked on with an early client. This doctor-led, orthopedic surgery tool manufacturer made high-tech hip and knee replacement equipment. Their newest tool was the acetabular reamer. The reamer’s purpose is to drill out a hemispherical hole in the patients pelvis to hold the cup half of the artificial hip joint. Think of this device like a home power drill. When the power tool is used to drill wood too forcefully, friction between the drill bit and wood creates heat which galvanizes the chemical reaction of burning. Same thing sort of happens between the reamer head and pelvic bone cells except when friction heats the bone cells to greater than 131 °F, the cells not only burn, they die. This cell death, called necrosis, is the leading indicator of an unsuccessful replacement surgery. If there are too many dead bone cells the acetabular cup will not establish a good fit after being inserted, and over time it may move or rock with walking, creating great pain to the patient and great cost to the customer (hospital, clinic) to finance the necessary redress surgery. Currently 6% of patents need a redo after 5 years and 12% need it after 10 years.

The innovation then, and the way the smart acetabular reamer differentiates itself, is to never kill bone cells. Full stop. The rotational speed of the reamer head is controlled so that no matter how much pressure the surgeon applies and for however long it’s applied, its rotational speed will slow enough to prevent necrosis.

This results in a more competitive medical device. One that is more innovative and differentiated from its competitors. And a device that delivers faster and more cost-effective surgeries for the customer while leaving patients happier and healthier. This is how market share is gained.

HOW IT’S DONE

The first step in making the acetabular reamer smart is to virtualize it with a value sim developed with primary data. In this case its AI model is built around:

Pelvic bone cell temperature = (rotational speed, pressure, time)

Embedded software within the device executes the simulation by inputting the real-time pressure and time data gathered by sensors in the instrument. The new and safer speed is calculated by solving for rotational speed. If the pelvic bone cell temperature is estimated to approach the necrosis temperature the embedded software slows down the rotational speed of the acetabular reamer to cool things down.

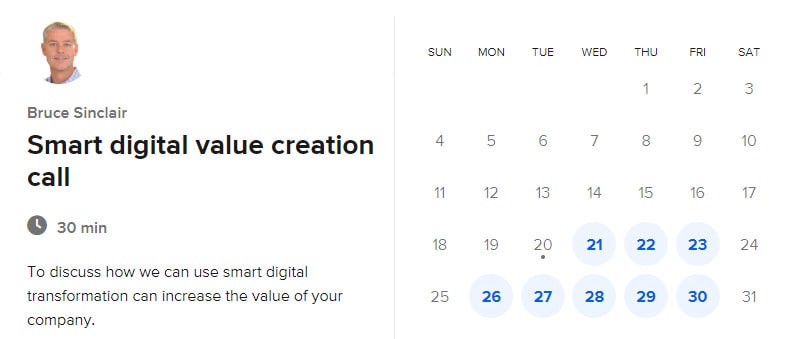

Contact us if you’d like to understand more or click calendar to schedule a free 30-minute consultation if you have a company to improve.