25 May Delevering Asset-Heavy PE Businesses with Smart Tech AI

So far in this series we’ve discussed the smart digital P&L value levers, revenue growth, margin improvement, pricing optimization and buy & build boosting. Here, we’ll discuss the last smart value lever, debt management, by looking at how asset heavy businesses can unlock value off the P&L by generating free cashflow to pay down debt. Two ways I’ve used smart digital to improve working capital are with asset utilization and inventory control.

Two of the ways I’ve used smart digital to improve working capital are with asset utilization and inventory control.

Although related to operational efficiency, an asset’s utilization is independent of its performance. It’s more about improving capital efficiency by generating more revenue from existing assets without having to invest in more. This was the case for a sponsor-owned precision manufacturer in the aerospace industry I worked with. Their business was booming, so much so that to keep up with demand they were outsourcing manufacturing and buying high-precision equipment indeterminately. By better understanding and predicting their different manufacturing lines’ needs they were able to increase their specialized machine utilization rate from 40% to 70%. This reduced their overall CAPEX spending by 10% by avoiding having to buy another two new machines, as they did the previous year when business started on the ramp up.

As a segue to traditional inventory control, internal operational asset inventory control can also increase asset utilization, but in a different way. Asset tracking, as the name implies, is about knowing where all operational assets are so they can be used more instead of buying new ones. Whether it’s keeping track of aircraft towbars in an airport or tracking pavers shared between geographically dispersed road construction jobs, just knowing where shared operational assets are can increase capital efficiency and working capital for many service businesses.

Inventory control, in the more traditional sense, can also have a positive off-P&L impact on industrial and manufacturing companies. Reducing excess inventory frees up valuable working capital to be used elsewhere. Better predicting inventory needs leads to just-in-time (JIT) inventory but it can also be strategic. Take for example a sponsor-owned OEM of oil and gas equipment. They were losing repair business by not having the needed replacement parts available quickly enough to repair broken customer equipment. By replacing an antiquated, mostly paper-based decentralized inventory system with an online database that used AI to inform manufacturing timing and buying decisions, they were able to predict when to build or buy parts based on equipment history. Smart inventory control enabled the OEM to reduce replacement part inventory by 25%, but more importantly, it enabled my client to respond to high-margin repair requests that was previously out of reach due to not having the required parts immediately available after a breakdown.

Asset heavy businesses can unlock value off the P&L with smart digital asset utilization and inventory control initiatives. Asset utilization is improved by better scheduling individual assets such as manufacturing equipment, and groups of shared assets such as the operational equipment used in many service businesses. Inventory control applies to both shared operational equipment and to the input parts and material used in manufacturing. The examples cited here used AI to predict utilization, usage and consumption to generate more free cashflow to pay down debt by improving working capital. More about the examples discussed here can be found in the case study section.

HOW IT’S DONE

The asset utilization and inventory control examples cited here rely on artificial intelligence models to make predictions about the future based on historic data. Often the most challenging aspect of this tech is called data wrangling: finding the data needed, often located in different forms and places, and then formatting and storing them in a homogeneous way. A training data set is partitioned to train the model. Once trained, new data is extracted, transformed and loaded into the model to output a scheduling prediction.

Smart internal equipment controls/inventory entail attaching tracking hardware to the shared assets and then networking them together to the tracking app in the cloud. This real time data is often displayed as a heatmap and is used to inform planning software to get the most out of a company’s operating equipment inventory.

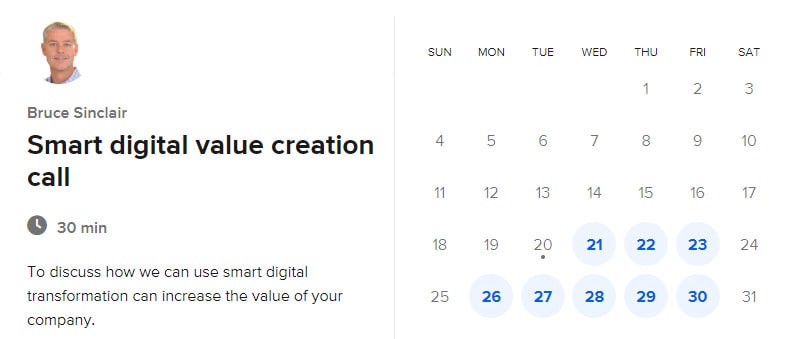

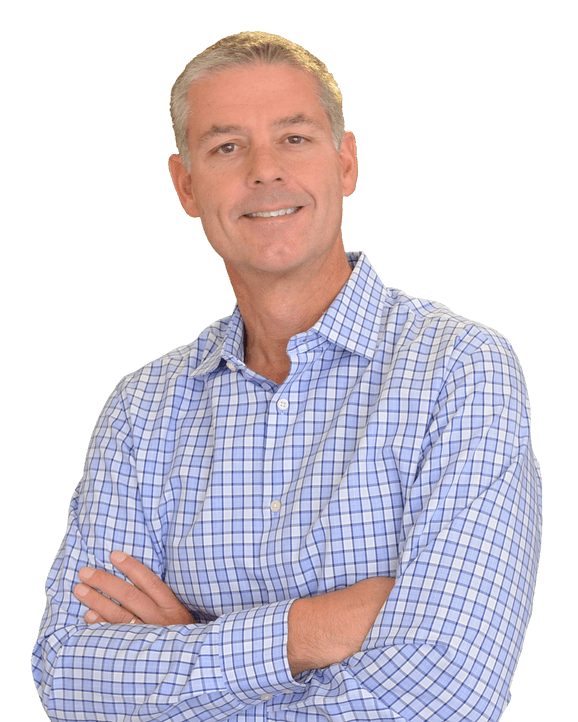

Contact us if you’d like to understand more or click calendar to schedule a free 30-minute consultation if you have a company to improve.